Filter Cloth in Construction: Enhancing Soil Stability and Drainage

Introduction to filter cloth in construction projects

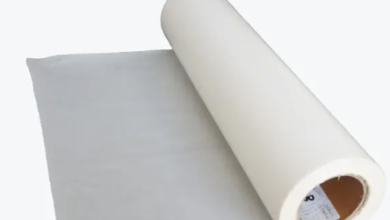

In civil engineering and infrastructure development, managing soil and water interaction is critical to the longevity of structures. Filter cloth is a type of geotextile widely used to separate soil from drainage aggregates while allowing water to pass through. It prevents soil migration, reduces erosion, and ensures the efficiency of drainage systems.

Filter cloth is commonly applied in roads, retaining walls, drainage networks, and erosion control systems. Its versatility and durability make it a key material in modern construction practices.

What Is filter cloth?

Filter cloth is a synthetic fabric, usually made from polypropylene or polyester fibers. It can be woven or nonwoven depending on the application. Its main functions include:

- Soil separation

- Filtration of fine soil particles

- Supporting drainage and water flow

- Erosion control

- Subgrade stabilization

Filter cloth allows water to move freely while preventing soil particles from passing through, which is essential for maintaining structural integrity in civil engineering projects.

Types of filter cloth

Nonwoven Filter Cloth

Nonwoven filter cloth is made by bonding fibers filter cloth in construction through needle-punching or thermal processes. It has high permeability and excellent filtration properties. Common applications include:

- Retaining wall backfill

- Road subgrade separation

- French drains

- Subsurface drainage layers

Its fibrous structure ensures efficient water flow while retaining soil particles.

Woven Filter Cloth

Woven filter cloth is manufactured by interlacing synthetic yarns. It provides higher tensile strength but generally lower permeability than nonwoven cloth. Woven fabrics are suitable for applications requiring additional reinforcement along with filtration.

See also: Why Businesses Are Turning To AI Speakers For Competitive Advantage

Key Performance Characteristics

Choosing the right filter cloth requires understanding its technical properties:

Apparent Opening Size (AOS)

AOS determines the largest soil particle that can pass through the fabric. Selecting the correct AOS ensures efficient filtration without clogging.

Permittivity

Permittivity measures the rate of water flow through the fabric. High permittivity allows proper drainage and reduces hydrostatic pressure behind structures.

Tensile Strength

Tensile strength ensures that the fabric can withstand stresses during installation and under soil loads.

Puncture Resistance

Puncture resistance is critical in construction environments with coarse aggregates or heavy equipment to prevent fabric damage.

Applications of filter cloth in construction

Retaining Walls

Filter cloth separates backfill material from native soil behind retaining walls. This prevents soil migration, maintains proper drainage, and reduces hydrostatic pressure on the wall.

Road Construction

In road and highway projects, filter cloth prevents subgrade soil from mixing with aggregate base layers. This improves pavement stability, reduces settlement, and extends service life.

Drainage Systems

Filter cloth surrounds gravel or perforated pipes in French drains and underdrains, allowing water to infiltrate while retaining soil particles.

Landfills and Environmental Projects

Filter cloth is used in leachate collection systems and drainage layers to prevent clogging and ensure efficient fluid transport.

Erosion Control and Coastal Protection

Under riprap or gabion structures, filter cloth prevents soil washout while maintaining water flow beneath protective layers.

Advantages of Using Filter Cloth

- Lightweight and easy to install

- Consistent filtration performance

- Reduced material volume requirements

- Cost-effective solution

- Supports rapid construction and long-term durability

These advantages make filter cloth a practical solution in various civil engineering and environmental applications.

Design and Installation Considerations

Soil Compatibility

Select a filter cloth with an opening size appropriate for the surrounding soil to prevent clogging.

Hydraulic Conditions

Consider water flow rates and pressure when selecting fabric properties. High-flow environments require higher permeability.

Installation Practices

Level the subgrade, overlap fabric seams properly, and place aggregates carefully to avoid tearing or displacement.

Environmental Protection

Cover exposed fabrics promptly to prevent UV degradation and ensure durability.

Contribution to Sustainable Infrastructure

Filter cloth supports sustainable construction by:

- Reducing soil erosion

- Improving water management

- Minimizing maintenance and repair costs

- Extending the service life of structures

It offers a long-lasting and environmentally responsible solution for modern construction projects.

Conclusion

Filter cloth is an essential material in civil engineering for soil stabilization, drainage, and erosion control. Its ability to retain soil particles while allowing water flow ensures the longevity and efficiency of retaining walls, roads, drainage systems, and environmental projects.

Proper selection, design, and installation of filter cloth help prevent soil migration, enhance drainage performance, and contribute to sustainable infrastructure development.

Frequently Asked Questions

What is filter cloth used for in construction?

Filter cloth separates soil from drainage layers while allowing water to pass through, preventing erosion and maintaining structural stability.

Should I choose woven or nonwoven filter cloth?

Nonwoven cloth is generally preferred for filtration due to higher permeability, while woven cloth is used where additional reinforcement is needed.

Can filter cloth reduce hydrostatic pressure?

Yes, it allows water to drain freely, reducing hydrostatic pressure behind retaining walls and other structures.

How long does filter cloth last?

With proper installation and protection from UV exposure, filter cloth can last for several decades.

Is filter cloth environmentally friendly?

Yes, it helps control erosion, improves drainage efficiency, and supports sustainable construction practices.