Heat Pipe Heat Sinks: Modern Solutions for Advanced Thermal Control

The demand for efficient electronics cooling continues to rise, with the global market projected to reach $11,653.3 million by 2031. This growth is driven by increasing heat output in applications such as data centers, aerospace systems, and renewable energy equipment. As electronic components become more powerful and compact, traditional air-cooling approaches struggle to manage the resulting heat loads. Due to this, heat pipe heat sinks have become a widely adopted solution for effective thermal management.

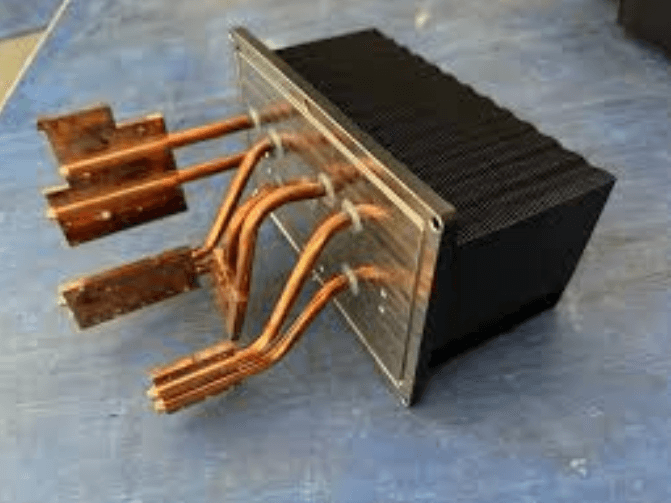

These cooling systems combine the extended surface area of heat sink fins with the rapid heat transport capability of heat pipes. Together, they provide a reliable means of dissipating heat from critical components and maintaining stable operating temperatures. The sections below explain how heat pipe heat sinks are constructed, their operational principles, and their common applications.

Understanding Heat Pipe Heat Sinks

A heat pipe heat sink is a cooling assembly that integrates one or more heat pipes into a conventional heat sink structure. Heat pipes quickly transfer thermal energy away from concentrated heat sources, spreading it across a larger area where the heat sink can release it into the surrounding air through convection and radiation.

Each heat pipe is sealed and contains a working fluid, such as distilled water, ammonia, methanol, or acetone. As the fluid absorbs heat, it changes phase from liquid to vapor and later condenses back into liquid. A built-in wick structure returns the liquid to the heat source using capillary action, enabling continuous and efficient heat transfer with minimal thermal resistance.

Why Heat Pipe Heat Sinks Are Effective

By distributing heat more evenly across the fin structure, heat pipe heat sinks reduce temperature spikes that can negatively impact electronic components. Their ability to manage high heat flux makes them well-suited for cooling CPUs, GPUs, and power electronics, where operating temperatures can reach up to 95°C.

Advanced designs are capable of dissipating 300 watts or more, offering significantly improved performance over standard air-cooled heat sinks. This makes them especially valuable in systems with limited airflow or high thermal demands.

Advancements in Heat Pipe Heat Sink Technology

The adoption of heat pipe heat sinks has grown in tandem with increasing power densities in industries such as computing, aerospace, and telecommunications. As electronic systems became smaller and more powerful, traditional heat sinks alone could no longer provide adequate cooling.

This limitation led to widespread use of heat pipe technology in compact devices and airflow-restricted environments. Continued improvements in materials, particularly copper and sintered metal structures, have further expanded performance capabilities. Today, some heat pipe heat sinks can handle thermal loads exceeding 500 watts, especially in industrial and data center applications.

Design and Operating Principles

Main Components

A typical heat pipe heat sink includes heat pipes, fins, a base plate, and an internal wick structure. The base plate absorbs heat directly from the component, while the heat pipes transport that heat away from the source. The wick structure enables fluid circulation within the heat pipe, and the fins increase surface area to improve heat dissipation.

Together, these components form an efficient and durable thermal management system.

How the Cooling Cycle Works

Heat pipe heat sinks operate using a two-phase heat transfer process. When heat is applied at the evaporator section, the internal fluid vaporizes and moves toward the cooler condenser region. There, the vapor releases its heat and condenses back into liquid form. The wick structure then draws the liquid back to the heat source through capillary action, allowing the cycle to repeat continuously.

This process enables rapid heat movement with very low thermal resistance. Heat pipe heat sinks can achieve thermal resistance values as low as 0.01°C/W, compared to approximately 0.04°C/W for conventional air-cooled heat sinks.

Design Configurations

Heat pipe heat sinks are available in various layouts to suit different applications. Common configurations include multiple heat pipes embedded in a base plate for CPU and GPU cooling, direct-contact designs that reduce thermal interface resistance, and U-shaped or vertically arranged heat pipes for compact enclosures.

Fin geometry and orientation are carefully designed to balance airflow resistance with optimal cooling performance.

Read also: The Evolution of Sustainable Packaging Through Laser Marking Technology

Material Choices

Copper and aluminum are the primary materials used in heat pipe heat sink construction. Copper offers excellent thermal conductivity (398 W/m·K) and is commonly used for heat pipes and base plates. However, its higher weight and cost can be limiting factors.

Aluminum provides lower thermal conductivity (237 W/m·K) but is lightweight and cost-effective. It is typically used for fins, where large surface areas are needed to dissipate heat efficiently.

Advanced Cooling Enhancements

Modern heat pipe heat sinks often incorporate features such as vapor chambers or direct-contact heat pipes to further improve performance. Vapor chambers spread heat evenly across the base plate, reducing localized hotspots, while direct-contact designs eliminate intermediate thermal interfaces to enhance heat transfer.

These enhancements are widely used in servers, gaming systems, and other high-density electronic platforms where thermal control is critical.

Applications of Heat Pipe Heat Sinks

Heat pipe heat sinks are used across a wide range of industries, including:

- Consumer electronics (laptops, smartphones, gaming consoles)

- Data centers and server systems

- Telecommunications infrastructure

- LED lighting solutions

- High-performance CPUs and GPUs

- Industrial automation equipment

- Power electronics (MOSFETs and IGBTs)

- Medical imaging systems

- Solar power inverters

- Aerospace and satellite platforms

- Avionics and defense electronics

- Electric vehicle battery systems

- Semiconductor manufacturing equipment

In high-performance computing environments, these cooling systems can dissipate 100–300 W/cm². Aerospace applications rely on them to maintain stability across extreme temperature ranges from -150°C to +125°C. In industrial power electronics, heat pipe heat sinks help keep operating temperatures below 85°C, improving long-term reliability.

Key Perks

- High-efficiency heat transfer through phase-change operation

- Very high effective thermal conductivity

- Low thermal resistance over long distances

- Compact and lightweight construction

- Flexible installation orientation

- Rapid response to changing heat loads

- Ability to handle high heat flux densities

- Passive operation with no moving parts

- Long operational lifespan

- Customizable designs and form factors

- Suitable for vacuum and space environments

- Minimal maintenance due to sealed construction

These benefits allow engineers to meet strict thermal requirements without relying on active cooling methods, reducing system complexity and power consumption.