How a Filling and Capping Machine Solves Real Production Bottlenecks

Modern production lines are under constant pressure to deliver faster output, cleaner results, and consistent packaging quality. Among all types of packaging equipment, the filling and capping machine has become one of the most searched solutions because businesses need a reliable way to handle liquid products without slowdowns or unnecessary waste.

This article explores real bottlenecks faced on production floors and explains how a filling and capping machine directly solves them.

Common Production Bottlenecks That a Filling and Capping Machine Eliminates

1. Slow Manual Processes That Reduce Output

Manual filling is inconsistent. Workers get tired, mistakes happen, and speed drops throughout the day. Even semi-manual operations often rely on hand placement, manual tightening, or visual checks, which are not suitable for higher output needs.

A filling and capping machine eliminates these inconsistencies by:

- Maintaining the same filling speed all day

- Applying each cap with identical torque

- Reducing the number of operators required

- Allowing continuous operation without breaks

Instead of production slowing down at peak hours, the machine keeps the line moving smoothly.

See also: Conventional Geysers Are Making a Comeback: Here’s Why Homeowners Still Love Them

2. Inaccurate Filling That Causes Waste

Overfilling wastes product and raises production costs. Underfilling leads to customer complaints and regulatory issues. This is one of the biggest reasons companies search for a filling and capping machine.Modern systems use:

- Flow meters

- Piston filling accuracy

- Anti-drip nozzles

- Steady pressure control

These elements prevent inconsistent volume and reduce product loss.

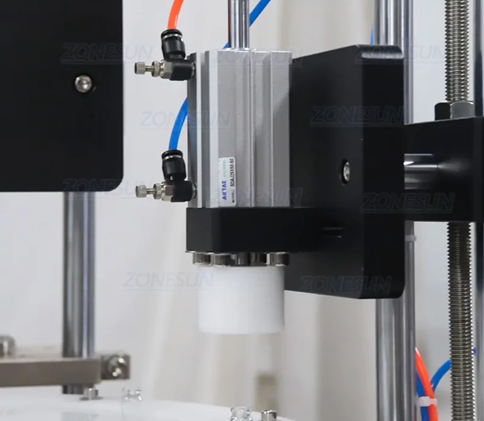

3. Cap Problems That Interrupt the Entire Line

Loose caps are a common cause of product rejection. Tightened too much? The cap breaks. Not tight enough? Leakage happens during transport.

A stable filling and capping machine prevents these issues by controlling:

- Torque accuracy

- Cap alignment

- Cap feeding speed

- Cap placement pressure

This gives brands more reliable end products and fewer returns.

4. Frequent Cleanup Interruptions

Without controlled filling, spills are inevitable. Even a few drops can create sticky buildup or require line shutdown for cleaning. That wastes time and reduces output.

Machines with:

- Drip-free nozzles

- Smooth surfaces

- Easy-clean structures

Help production teams maintain efficiency without repeated interruptions.

Why Filling and Capping Machines Are Becoming a Top Search Trend

Companies aren’t searching for these machines just because automation is popular—they’re searching because the real-world problems are too expensive to ignore.

Lower Labor Costs

Instead of several workers performing filling, wiping spills, tightening caps, and checking each unit, one operator can oversee the machine.

Consistent Packaging Quality

Uniform appearance directly influences brand trust. A filling and capping machine delivers consistent fill lines, clean bottle exteriors, and caps that look identical across every batch.

Faster Order Turnaround

More businesses operate under strict delivery deadlines. Machines reduce the risk of production bottlenecks, making orders easier to complete on time.

Key Features That Buyers Should Look For

A buyer searching for a filling and capping machine is usually comparing multiple models. These features help determine which machine is practical, reliable, and worth the investment.

Controlled Filling Heads

Multiple filling heads with adjustable height allow quick switching between bottle types.

Cap Sorting and Feeding Stability

A good capping system avoids jams and feeds caps smoothly through the line.

Touchscreen Control Panels

Factories prefer equipment with simple controls, allowing workers to adjust parameters without heavy training.

Sturdy Conveyor Alignment

Misaligned bottles cause spills and cap misplacement. A steady conveyor with guides is essential.

Quick Changeover Design

Buyers want machines that switch between different bottle sizes in minutes, not hours.

Conclusion

A filling and capping machine helps factories eliminate real production bottlenecks by improving accuracy, preventing spills, stabilizing cap application, and reducing labor pressure. When the machine is matched to actual workflow needs, it becomes a reliable tool that keeps daily operations efficient and consistent.