Custom CNC Machining: Tailored Precision for Every Industry

Introduction

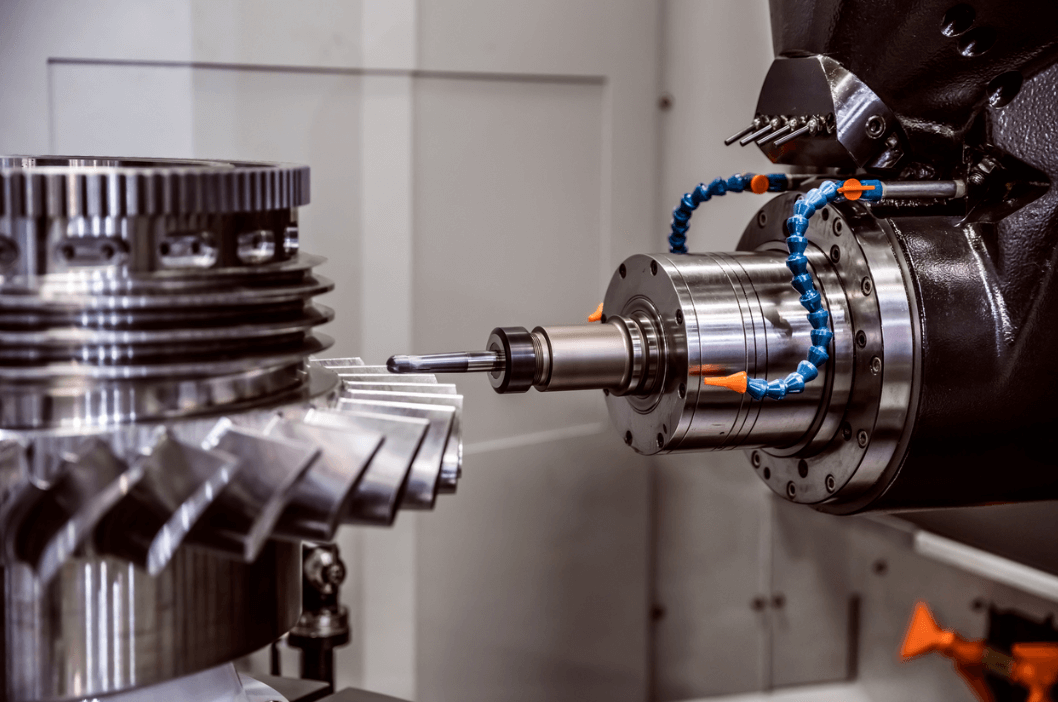

In today’s fast-paced industrial environment, standardized parts often fall short in meeting complex or specific requirements. Unlike mass production that churns out identical Custom CNC Machining focuses on delivering tailor-made parts with exact specifications. Whether it’s a prototype, a replacement part, or a limited-run component, this method offers unmatched flexibility and accuracy.

What Is Custom CNC Machining?

Custom CNC machining is a manufacturing process that uses computer-controlled machines to produce parts according to unique designs and precise tolerances. Instead of following a general template, each part is machined based on a specific CAD (Computer-Aided Design) file provided by the customer or engineering team.

This process is ideal for companies that require components unavailable in standard catalogs or those that must adhere to specialized operational or design constraints.

Why Go Custom?

Customization in CNC machining offers advantages beyond aesthetics. Here are some reasons why industries prefer custom solutions:

- Unique specifications: When off-the-shelf parts don’t meet your needs.

- Prototyping: For testing concepts before mass production.

- Repair and replacement: For legacy systems where original parts are discontinued.

- Performance optimization: Tailoring parts for better function, weight, or efficiency.

Custom CNC machining makes it possible to manufacture exactly what is needed, minimizing compromises and improving final product performance.

See also: China GJJ Hoist: A Global Standard in Construction Lifting Equipment

The Customization Process

Step 1: Design

Everything begins with a design. Engineers or designers create a 2D or 3D model using CAD software. This design outlines the exact dimensions, shapes, tolerances, and finishes needed.

Step 2: Programming

The design file is then converted into a set of instructions for the CNC machine using CAM (Computer-Aided Manufacturing) software. The tool paths, cutting depths, and speed are optimized for precision and material characteristics.

Step 3: Material Selection

Metals like aluminum, titanium, brass, and stainless steel are commonly used, along with plastics such as nylon, PEEK, and PTFE.

Step 4: Machining

The programmed CNC machine performs the necessary operations — milling, turning, drilling, or grinding — to create the part.

Step 5: Inspection

Every custom part undergoes quality checks using precision instruments like calipers, micrometers, and coordinate measuring machines (CMM).

Advantages of Custom CNC Machining

Precision Tailoring

Custom machining allows for ultra-precise tolerances. This is especially important in sectors like aerospace and medical where even a fraction of a millimeter can impact performance or safety.

Low to Mid-Volume Flexibility

Custom CNC machining is perfect for small to mid-sized production runs, especially when every part needs to meet strict individual criteria.

Design Freedom

With custom CNC machining, complex shapes and internal geometries are no longer a limitation. Engineers can think beyond traditional design boundaries.

Quick Turnaround

Thanks to rapid prototyping capabilities and advanced machine programming, custom CNC parts can often be delivered in days instead of weeks.

Common Applications

Custom CNC machining is used across a wide range of industries. Here’s how it serves different sectors:

Aerospace

From jet engine components to customized brackets and housings, aerospace relies heavily on custom machining for parts that meet strict safety standards.

Medical Devices

Orthopedic implants, surgical tools, and dental components often require custom solutions due to the unique anatomy of individual patients.

Electronics

When compact, high-performance parts are needed for electrical systems or enclosures, custom CNC machining offers the required miniaturization and precision.

Robotics

Robotic arms, end effectors, and motor housings are often custom-made to ensure smooth integration with the rest of the automation system.

Challenges of Custom CNC Machining

Although the process is beneficial, it’s not without challenges:

- Higher Costs: Initial setup and one-off production are typically more expensive per unit compared to mass manufacturing.

- Complex Programming: Custom designs may require more time to program and test before production.

- Material Constraints: Some designs may demand materials that are harder to machine or more costly.

- Longer Lead Times for Unique Designs: For highly complex parts, the first production run might take longer due to iterations and testing.

Despite these challenges, the benefits of precision and specificity often outweigh the downsides.

Choosing a Reliable Partner

If your business relies on high-quality custom parts, selecting the right Custom CNC Machining service provider is critical. Here’s what to look for:

- Experience: Look for companies that have worked across industries with diverse design requirements.

- Capabilities: Ensure the manufacturer can handle multiple materials, offer 5-axis machining, and support prototyping through to production.

Future of Custom Machining

The future of Custom CNC Machining is promising, thanks to innovations in digital manufacturing, automation, and material sciences.

- Cloud-Based Manufacturing: Platforms now allow real-time collaboration between designers and machine shops across the globe.

- AI Integration: Machine learning algorithms optimize tool paths and anticipate wear or tool failure for higher accuracy.

- Digital Twin Technology: Engineers can simulate real-world performance of parts before manufacturing them.

- Sustainability: Eco-friendly coolants, recyclable materials, and efficient chip removal systems are making CNC machining greener.

As demand for customization grows, especially in areas like electric vehicles, renewable energy, and biotechnology, CNC machining will play a central role in transforming ideas into reality.

Conclusion

Custom CNC Machining is revolutionizing the way industries approach manufacturing. By offering the flexibility to produce components tailored to exact requirements, this method supports innovation, reduces waste, and enhances product performance across sectors.

In a world where precision and uniqueness are becoming the norm rather than the exception, custom CNC machining stands out as the go-to solution for businesses that refuse to compromise on quality or complexity.